Our ONE range products.

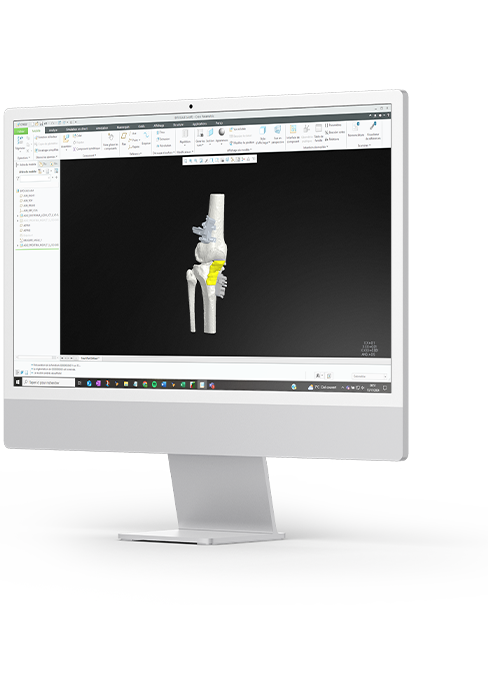

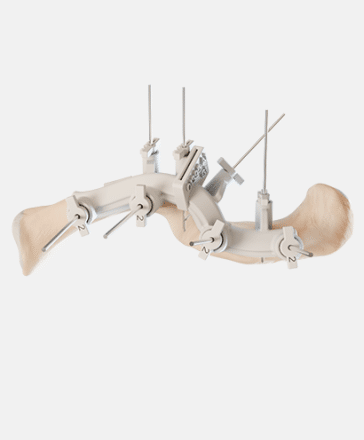

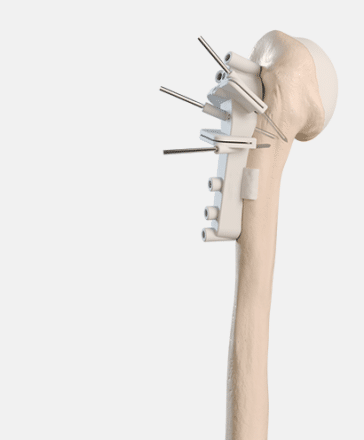

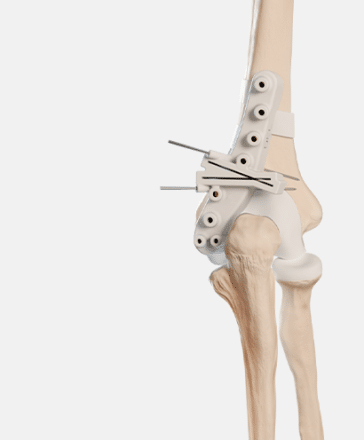

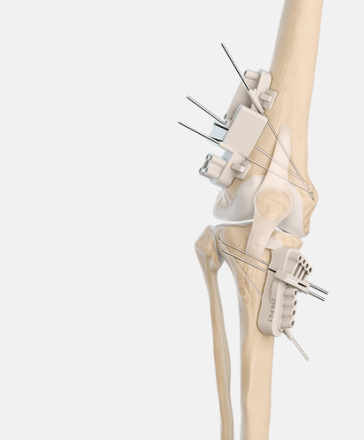

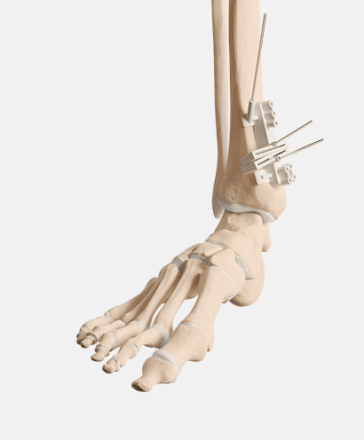

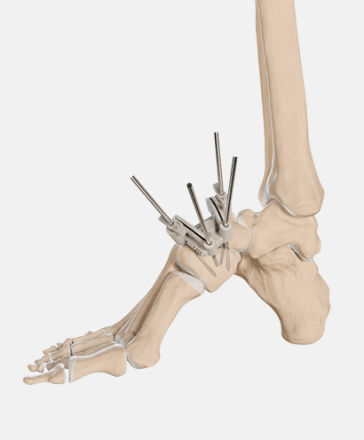

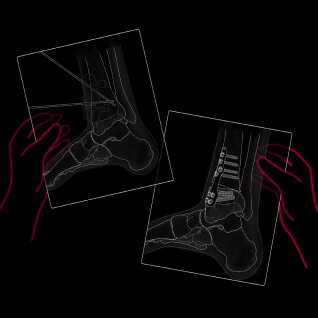

The ONE solution is a range of patient-specific cutting guides designed to support surgeons in 2D and 3D planning.

The ONE solution originated from a 2014 doctoral thesis on “Preoperative planning for osteotomies around the knee: From a three-dimensional digital model to the industrialization of patient-specific guides.” It was driven by the renewed interest of orthopedic surgeons in valgus tibial osteotomy. The objective of this thesis work was to understand the challenges of this surgery in order to make the surgical procedure safer.

The close collaboration established with expert surgeons in this field led to the creation of this division. The ONE solution was thus launched in 2017 for knee osteotomies before expanding its services to other anatomical sites, both in the lower and upper limbs.

The advantages of the ONE solution.

PRECISION

The ONE solution optimizes the precision of :

- The positioning of the cutting plane

- The correction in the 3 planes

- The positioning of the plate

SAFETY

The ONE solution protects :

- The hinge, particularly for lower limb osteotomies

- The soft tissues, such as the patellar tendon, during tibia osteotomies

REDUCED OPERATING TIME

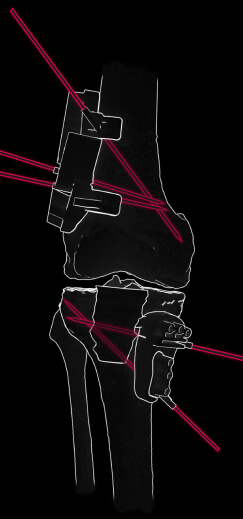

The ONE solution helps reduce operating time once the learning curve is achieved, thanks to:

- Preoperative planning of the correction and plate positioning

- Guided drilling of the plate holes

- Predetermined screw lengths

All steps of the surgery are summarized in a surgical technique sent with the cutting guide.

REDUCTION OF THE NUMBER OF FLUOROSCOPIES

The ONE solution helps reduce operating time once the learning curve is achieved, thanks to:

- Two fluoroscopies to validate the positioning of the guide

- One optional fluoroscopy to check the cutting depth

- Two fluoroscopies to validate the final assembly

ADAPTABLE

The ONE solution offers surgeons the possibility to benefit from a number of options:

- Patient-specific wedge

- Ligamentoplasty guide

- TTA transposition guides

- Femoral head cutting guide

- Iliac graft cutting guide

- Bone substitute cutting guide

- 3D printed preoperative bone

- 3D printed postoperative bone

The ONE Timeline.

- A CT scan following the Newclip Technics protocol

- The side to be operated on

- The type of surgery

The following information can be provided later :

- The correction to be applied

- The date of the surgery

- The desired plate

- The requested options

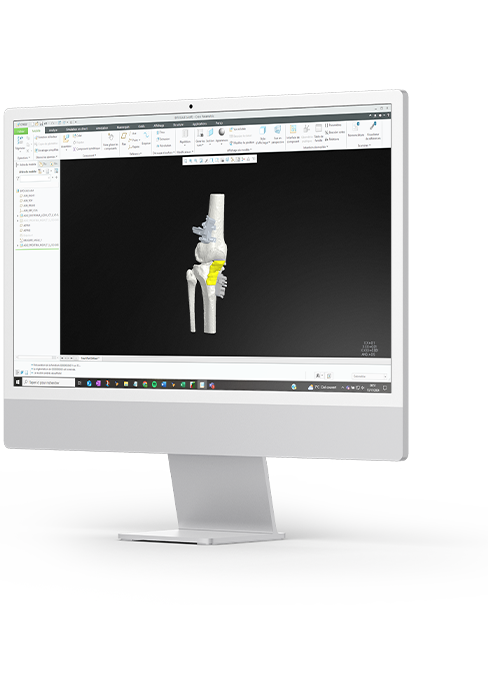

Once the case is accepted, you will receive an initial simulation file (measurements and/or correction simulation).

You will then need to validate or request modifications for:

- The position of the cutting plane

- The correction in the 3 planes

- The positioning of the plate

- The choice of plate

- The different options requested

Once you validate the simulation file, the team can then design the patient-specific guide and the associated options. It will be printed, cleaned, and packaged, then shipped non-sterile.